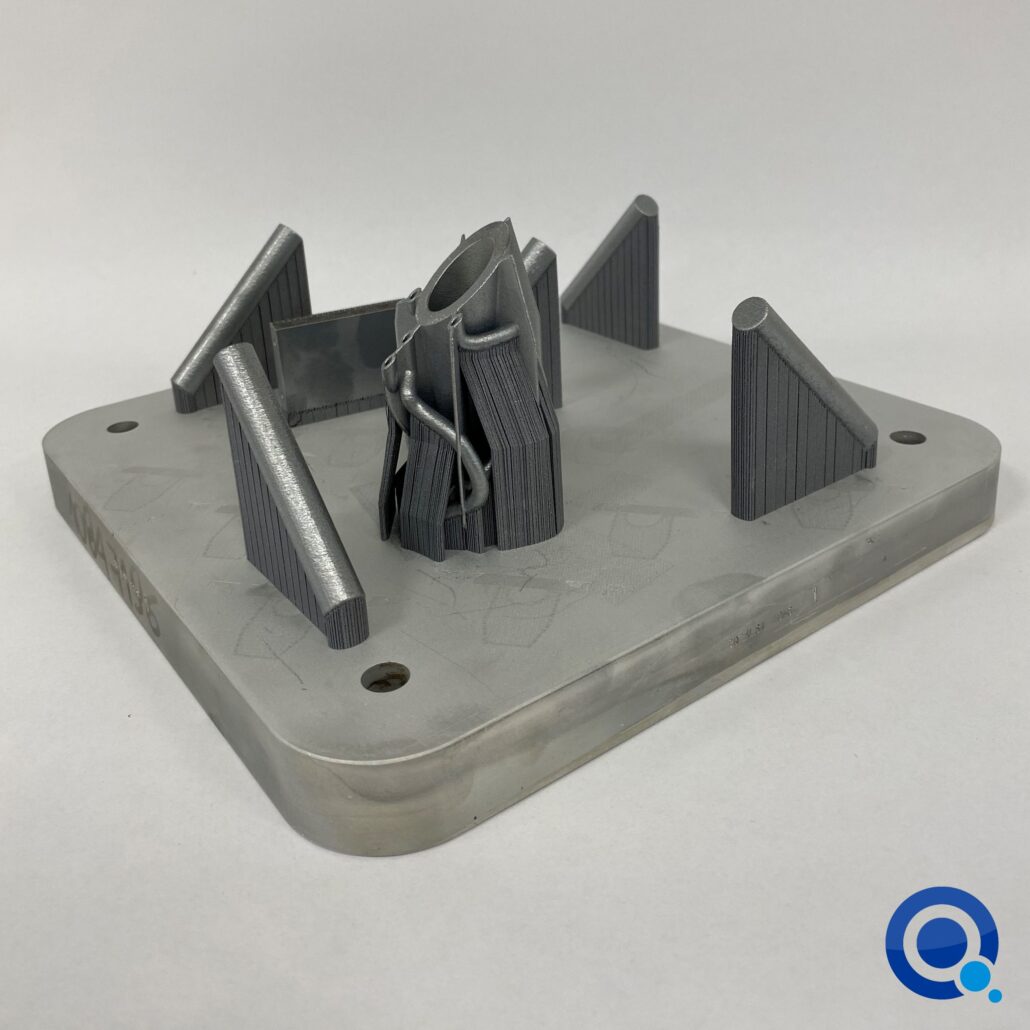

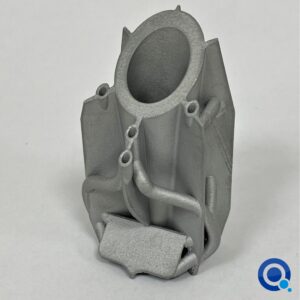

In DMLS, a laser melts the metallic powder layer by layer until the part is fully formed. Unlike SLS technology, SLM melts the powders into a uniform mass rather than sintering them. The metallic powders used in SLM/DSLM do not contain low melting agents, which makes the laser’s action more powerful. Materials commonly used include cobalt chromium, aluminum alloys, titanium, steel, nickel, bronze, copper, and silver.

This technology offers high precision and detail accuracy, making it suitable for creating metal prototypes ready for testing or finished parts ready for post-processing, including surface treatments, turning, heat treatments, and milling. DMLS/SLM is ideal for small-batch production, thanks to its fast execution and the elimination of tooling costs.

Benefits and applications of SLM/DMLS technology

The ability to produce a part—whether a finished product or a prototype for testing—through a simple and fully automated process significantly reduces both costs and production time. SLM/DMLS also facilitates the creation of complex geometries in a single piece, making it suitable for a wide range of industries, including:

- Automotive

- Aerospace and Aeronautics

- Naval

- Motorsport (reducing chassis weight with high-performance materials)

- Biomedical (small batches and client customization)

- Architecture and Home Design