Service Lab

Controllo Qualità srl. offers a full range of services to support our clients throughout the product development process – from the concept to the finished product, ready for its intended use.

Why choose Controllo Qualità srl. Because of our extensive set of measuring tools, our qualified technical staff, our flexibility that allows for a short throughput time, and our cutting-edge and constantly up-to-date technical skills.

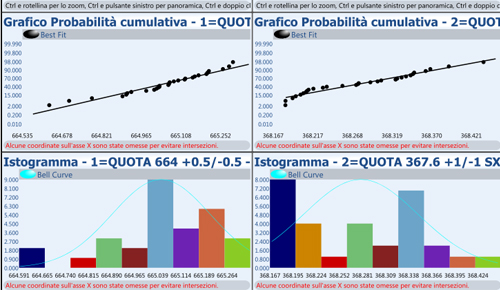

Dimensional Testing

An appropriate, agile and effective dimensional testing and control service with safe and fast response times. We examine the best available technology to perform dimensional testing, we check and identify possible critical issues, and we define the report in collaboration with our client according to the necessary fields and statistics.

Laser Scanning

A groundbreaking hybrid scanning system: flexible, powerful and accurate. The laser head, attached to a 7-axis probing arm, ensures extreme accuracy in data acquisition.

Surfaces to be scanned and digitalized are captured in the form of a point cloud image depicting and reproducing every single detail of the scanned object.

Also, the portability of the laser-headed anthropomorphic arm allows measurements to be conducted right at the client’s location.

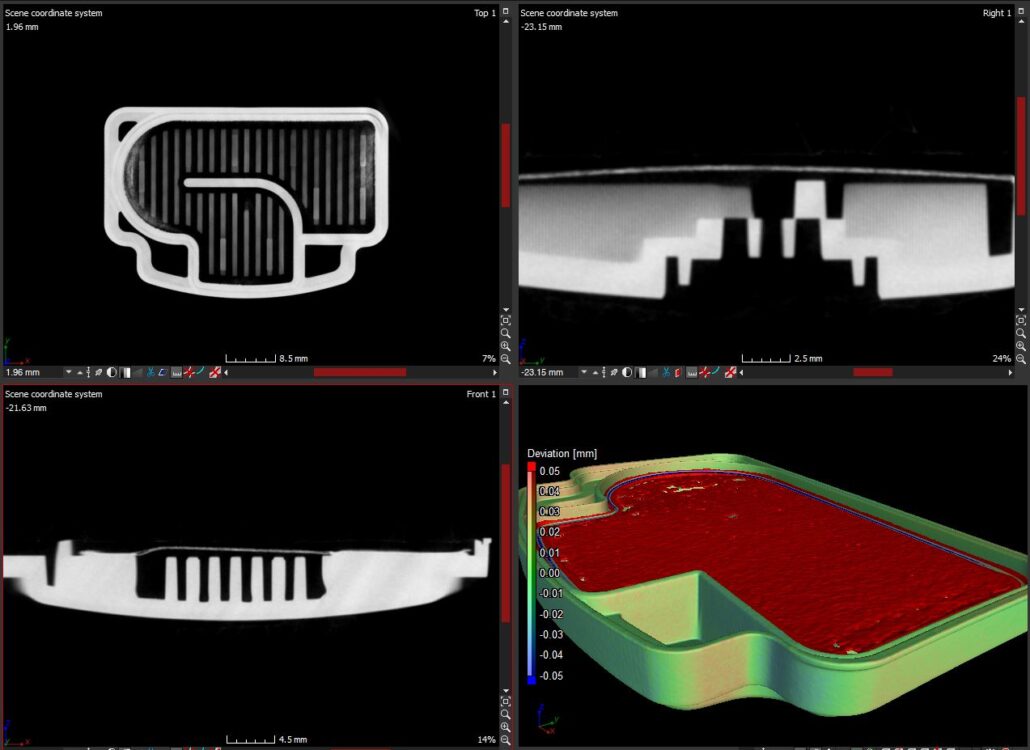

Tomography

Tomography allows many challenging surveying processes such as multiple parts simultaneous analysis, scanning superimposition with its mathematical model, failure analysis, three-dimensional controls, and complete internal and external 3D reconstitutions of the component.

In addition, it allows 3D reconstitutions of antiques, works of art, and musical instruments without any alterations to the original item specimen.

Acceptance checks and process analysis

Controllo Qualità srl. supports its clients by undertaking acceptance checks, becoming directly involved with the supply chain. All material is brought to our facility, processed and monitored according to the guidelines and any previously agreed upon sampling plans. We can also undertake minor assembly and the non-completion of processing steps in order to grant our clients ready-to-use components.

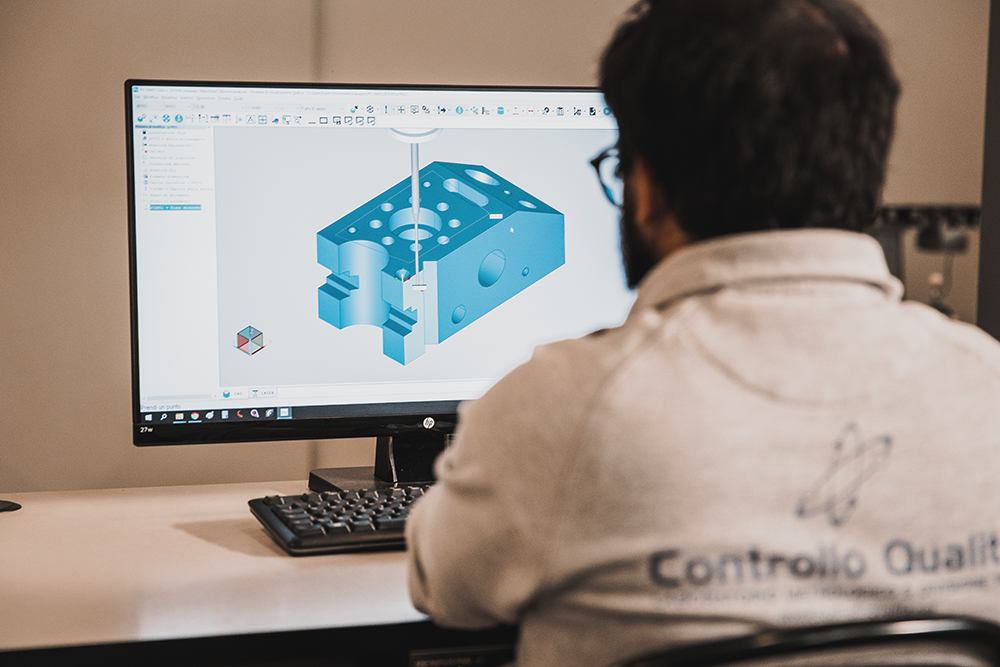

Offline Programming

We can make software-based measuring programs for CMM with the sole support of the three-dimensional model of the part to be measured. Software-based programming takes place at the Controllo Qualità srl. headquarters: Our client is provided with the file that contains the measuring program.

We offer a comprehensive tool kit for every part that will be put into production, including components clamping systems and its dedicated reporting pertaining to part control – both in process and in testing.

Fastening systems

Fastening systems: accuracy, flexibility and reproducibility

Whether for inspection applications in the automotive, electronics, homedesign, industrial or medical fields, we can provide a fully comprehensive fastening solution for virtually any part.

Our fastening systems increase the efficiency and improve the repeatability and accuracy of the inspection processes. Fast, replicable and easy to setup fasteners that do not require skilled manpower.

Fastening parts are adjustable and designed to secure parts by applying only a minimum necessary force in order to avoid damaging or deforming the actual parts.

Training

Controllo Qualità srl. provides customized training courses to you and your company’s employees to help you achieve better efficiency and skill in measurement and control processes.